37SGB STUMP GRINDER

SPECIFICATIONS

ENGINE:

Briggs & Stratton Vanguard V-Twin 37hp

DETAILS:

Height: 49.5″

Length (head to side): 79″

Length (head straight): 98″

Width: 35.5″

Weight: 1,950 lb.

Hydraulic Reservoir: 14 gallons

Hydraulic Flow to Head: 13.3gpm

Track Width: 7.1″

Total Ground Contact: 470 sq. in.

Ground Drive Forward: 290 ft/min

Ground Drive Reverse: 180 ft/min

WHEEL SPECIFICATIONS

Cutting Wheel: 19.2″ diameter to tooth

Cutting Teeth: 0.97 thick, 16 green teeth

Cutting Depth: 12″

Cutting Height: 32″

Head Swing: 134˚, 99.7″ arc

FEATURES

- Easy controls operate the track drive and cutter wheel

- Time-tested track design absorbs impact and provides stability

- Center-mounted cutter wheel provides 134º head swing

- Piston pumps coupled to the engine drive the cutter wheel, tilt, and swing

- Counterbalance valves on each track drive prevent motors from slipping

WHY BARRETO?

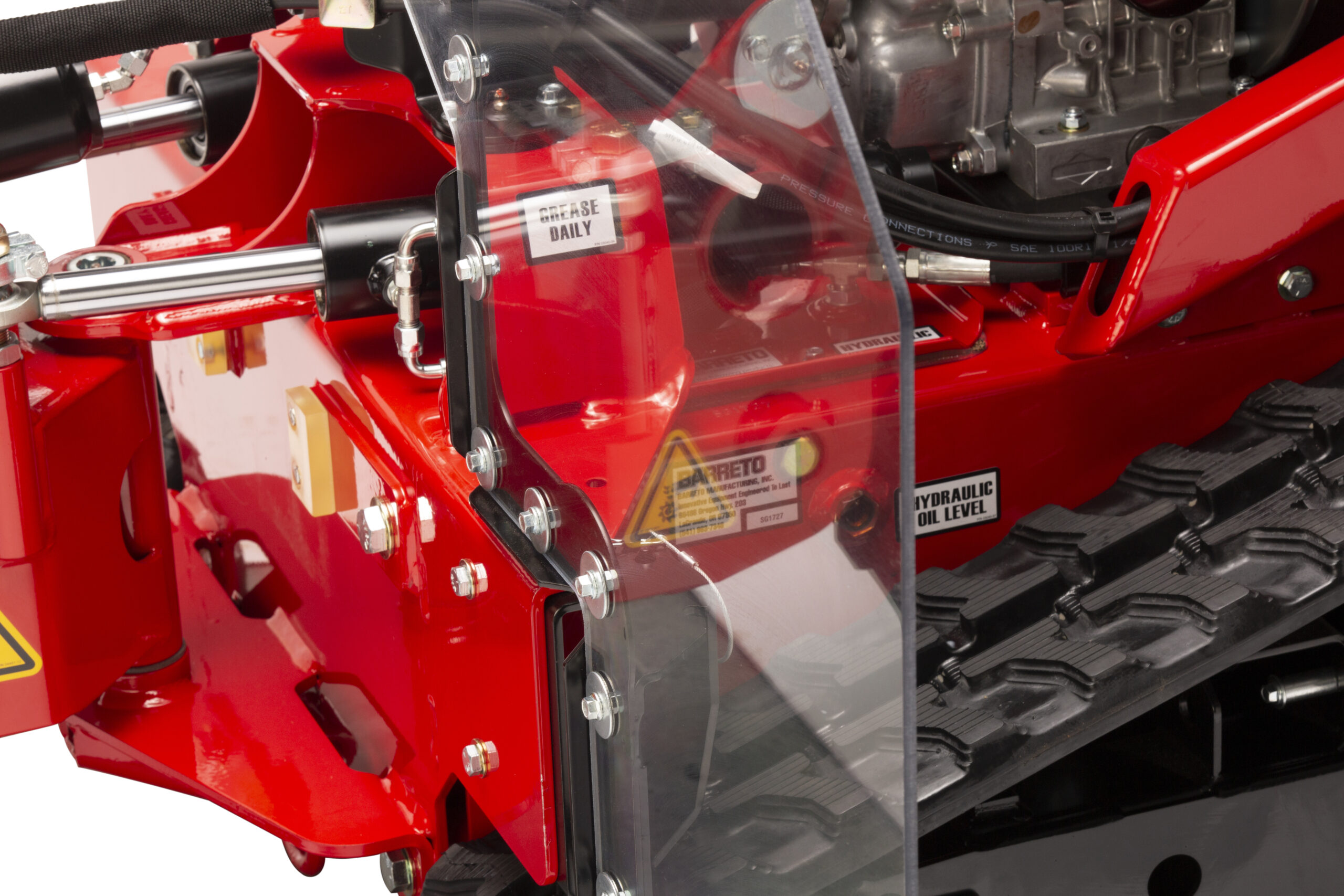

The 37SGB track stump grinder is a recent addition to the Barreto tree service equipment line. Designed on the reliable track drive platform used by the Barreto 30SG stump grinder, the 37SGB features a hydraulically-driven cutter wheel fitted with sixteen 900-series Green Teeth. The 37SGB is powered by a 37hp EFI Briggs & Stratton Vanguard V-Twin engine. The engine is coupled to a piston pump: the larger piston pump delivers fluid to a piston motor that drives the cutter wheel. The cylinders, lift, and swing are supplied with fluid from an auxiliary pump that is mounted to main piston pump. The tracks are driven by independent hydrostatic pumps mounted on the rear of the engine for easy access and simple linkage control. Counterbalance valves on each track drive prevent the track motors from slipping while the cutter wheel is engaged in the cutting process, even while operating on a slope. The track drive increases maneuverability around the jobsite, allowing the job to get done with increased efficiency.

The cutter wheel operation and articulating arm are operated by controls mounted on the console. The cutter wheel is activated by a switch on the control stick and has a secondary safety switch to prevent accidental engagement. Back and forth movement across the stump, as well as depth of cut, are easily controlled by handles on the console, allowing for carefully controlled movement of the cutter wheel as it reduces the stump to chips.

All hydraulic drive to the cutter wheel eliminates costly belts. It also increases customer satisfaction by ensuring there is no loss of power because of a damaged belt or mechanical component. The track drive increases maneuverability around the job site, creating customer satisfaction by allowing them to get the job done with increased efficiency.