SPECIFICATIONS

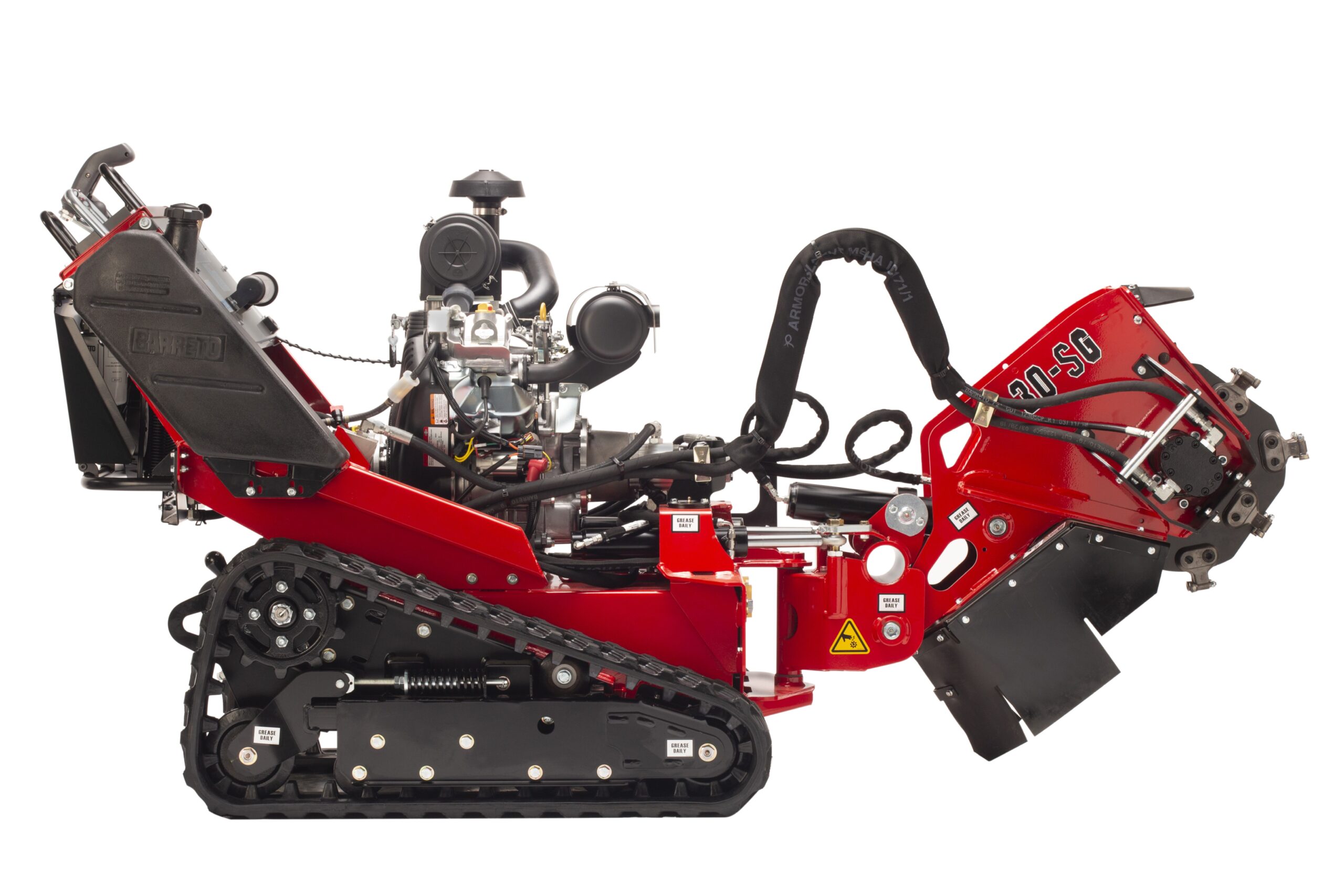

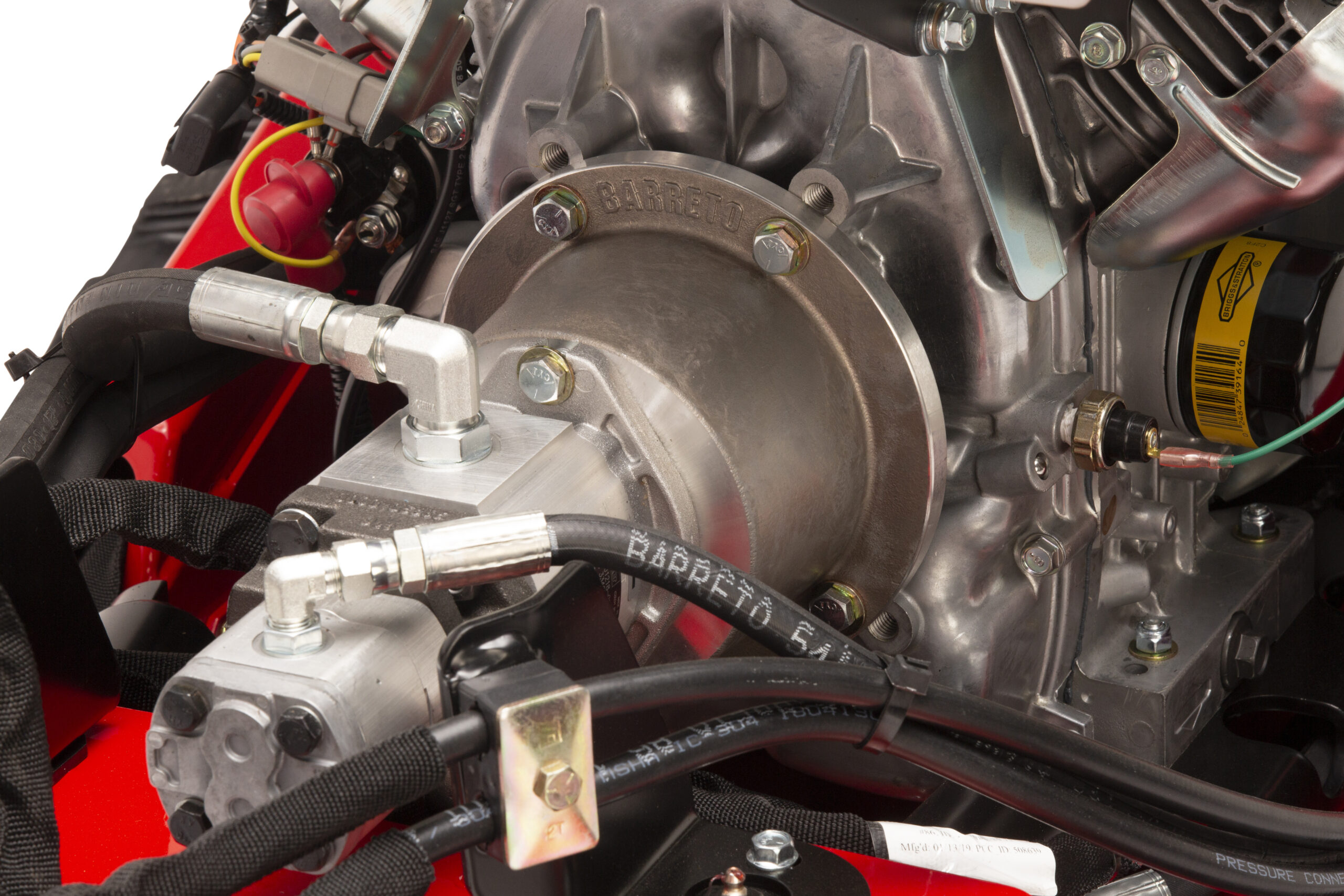

ENGINE:

Briggs & Stratton Vanguard V-Twin 31hp

DETAILS:

Height: 49.5″

Length (head to side): 79″

Length (head straight): 98″

Width: 35.5″

Weight: 1,700 lb.

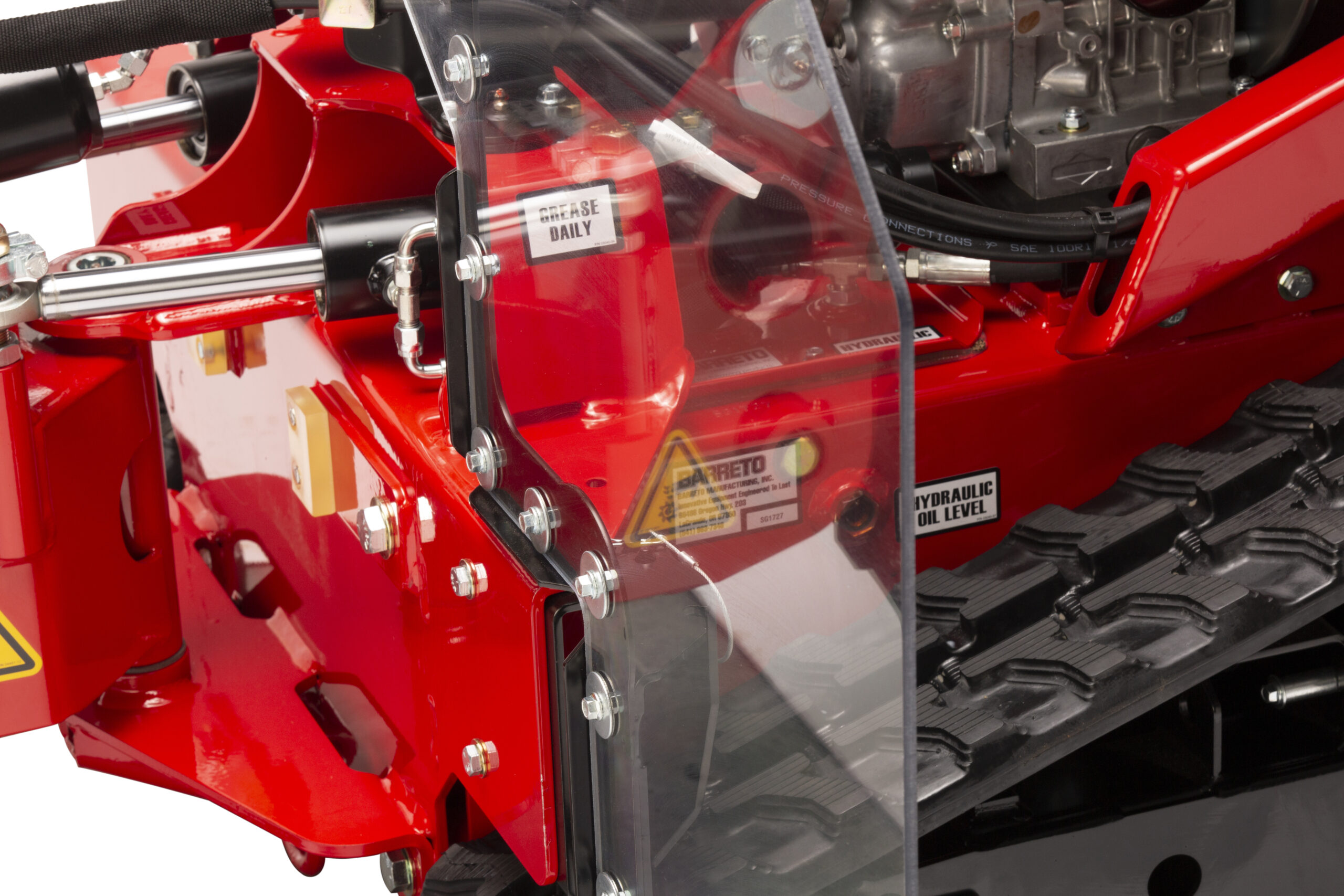

Hydraulic Reservoir: 14 gallons

Hydraulic Flow to Head: 13.3gpm

Track Width: 7.1″

Total Ground Contact: 470 sq. in.

Ground Drive Forward: 290 ft/min

Ground Drive Reverse: 180 ft/min

WHEEL SPECIFICATIONS

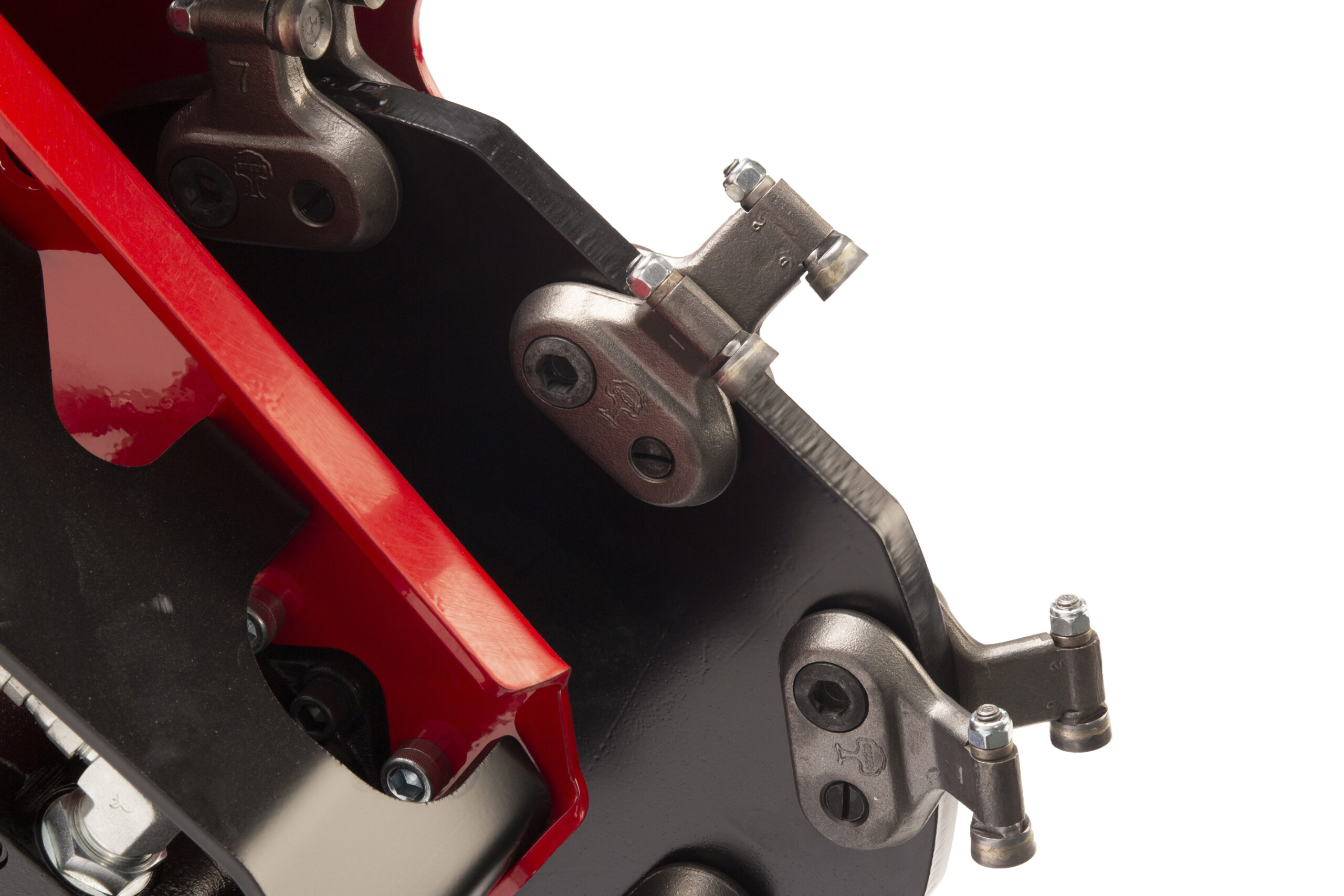

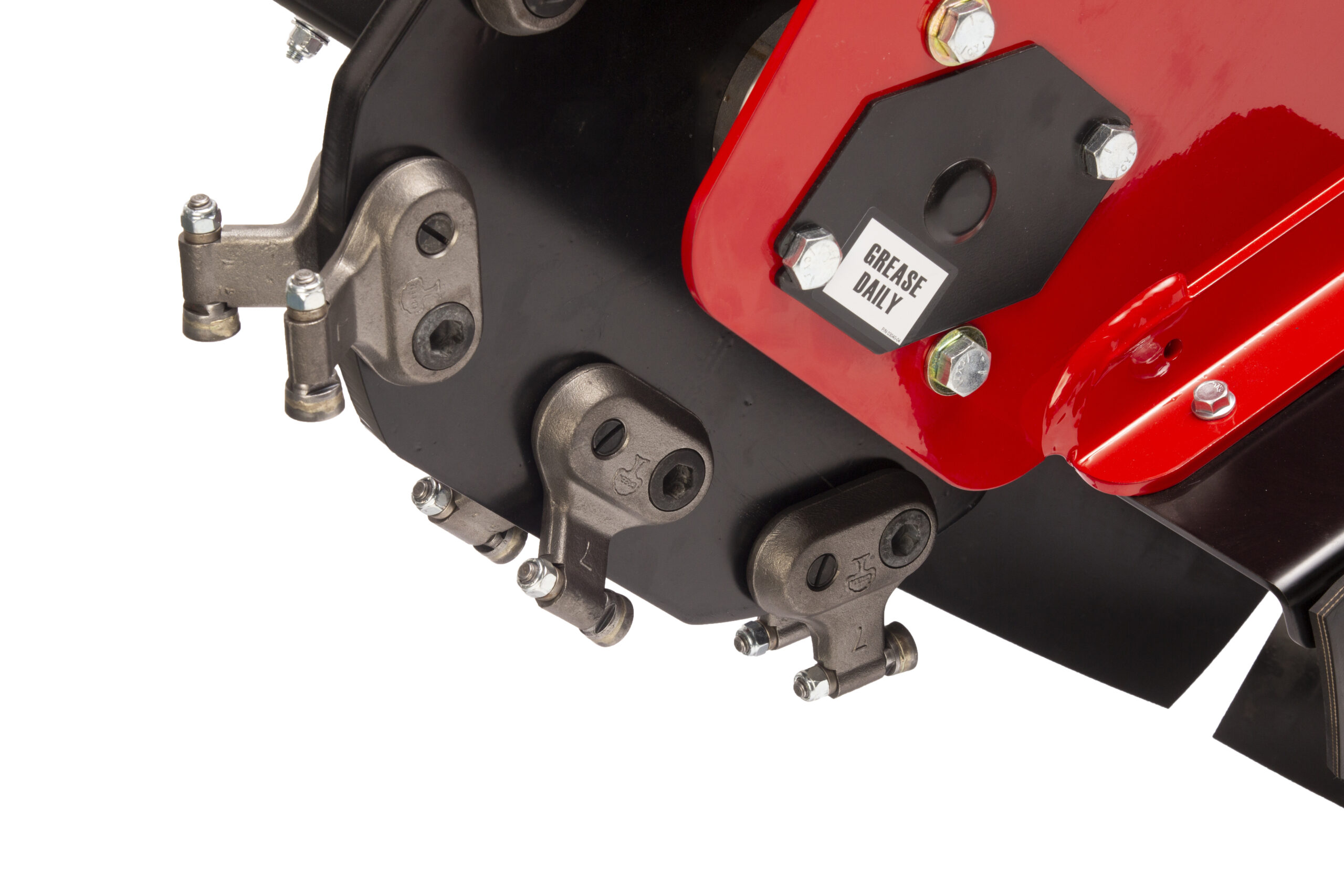

Cutting Wheel: 19.2″ diameter to tooth

Cutting Teeth: 0.750 thick, 16 green teeth

Cutting Depth: 12″

Cutting Height: 32″

Head Swing: 134˚, 99.7″ arc